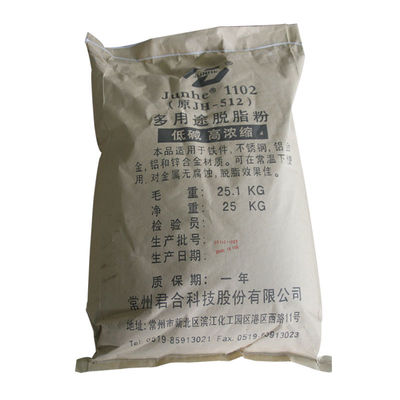

Low Foam Metal Pretreatment Chemicals Powder With Strong Permeability

Metal Pretreatment Chemicals Powder introduction

Metal Pretreatment Chemicals Powder Is a compound of surfactant with super penetration and emulsification, complexing agent, help lotion, has strong permeability, wettability, emulsification, natural biodegradable, in line with general international environmental protection standard. Commonly used as oil removal chemical in automobile, motorcycle, bicycle, household appliances, lighting, daily hardware and sanitary ware, such as all kinds of steel pieces before electroplating.

Metal Pretreatment Chemicals Powder Application

Be suitable in dipping and degreasing for steel/stainless steal/aluminum/aluminum alloy and zinc alloy work pieces.

parameter of Metal Pretreatment Chemicals Powder

| PH: |

11-13

|

Free Acid:

|

15-25

|

| Temperature: |

40-60 Degree

|

Time: |

3-15minutes

|

|

Aluminium Ion Content:

|

500PPM

|

Outlook: |

White Powder

|

Metal Pretreatment Chemicals Powder Detecting method:

Free alkalinity: pipet 10ml sample into 250ml conical beaker, add 2-3 dripping phenolphthalein indicator, after drop 0.1N hydrochloric acid till pink disappear. The consumption of the hydrochloric acid is same as free alkalinity.

Tatol alkali: pipet 10ml sample into 250ml conical beaker, add 2-3 dripping Bromine phenol indicator, after drop 0.1N sulphuric acid till green disappear. The total consumption of the sulphuric acid is same as total alkali.

We could calculate the ratio between total alkali and free alkalinity(TFR).

We could add 2kg JH1102 per 1000L BATH SOLUTION when free alkalinity increase 1point. The TFR will increase together with the Total alkali, and we could detect the pollution according to TFR.

Bath solution control: Max TFR will be different according to the different workpiecessolid impurity and temperature. We could drain the bath solution regularly in continuous flow or automatic flow to maintain the TFR lower than MAX TFR.

OEM model

1, OEM: Changzhou JUNHE Polytron Technologies Inc chemicals factory to undertake processing business of various chemicals. Provide all the raw materials, auxiliary materials, chemicals production formula, accessories, packaging materials, JUNHE production in accordance with the requirements of customers, product sales by the customer, JUNHE processing fee.

2, ODM: the customer is required to submit the chemical formula and technology service requirements, JUNHE technology to provide all the raw materials, accessories, accessories, packaging materials, finished products by foreign sales, Jun he collects all the material costs and processing fees. ODM from design to production by JUNHE technology to be completed after the product is molded by foreign bought.

3, venue rental: Jun provide the venue, equipment leasing services, customers in the production and processing workshop at. Jun, collect site equipment, hydropower coal leasing fees.

4, brand service: Jun from the formulation development, brand registration, production and processing to the sale of all in one service. R & D and sales at full participation in products.

Regardless of the way of cooperation, at full range to meet customer needs, from the formulation of R & D, production and sales, to provide comprehensive technical service and customer service guarantee.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!